Air-Conditioning System (Boiler-less AC)

:No use of petroleum fuels and gas

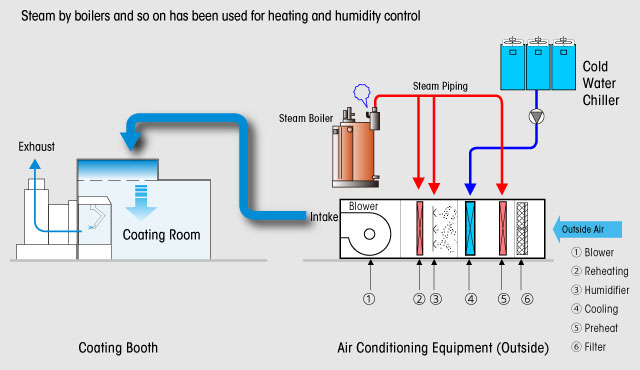

The conventional Air-Conditioning for Coating is an all fresh air method to intake fresh air from outside into the clean room and to exhaust the air from the coating booth directly to outside. The system is controled by heating with a steam boiler and humidifying with a steam as heat source.

There are some problems in this system as follows.

- High thermal energy is required because heating needs a lot of steam.

- Even during summer, boiler operarion is necessary for re-heating.

- Condensation of the steam occurs in the intake air duct after heating so that it provides some humidifying loss and wet filter of the clean room.

- Daily maintenance work of the boiler.

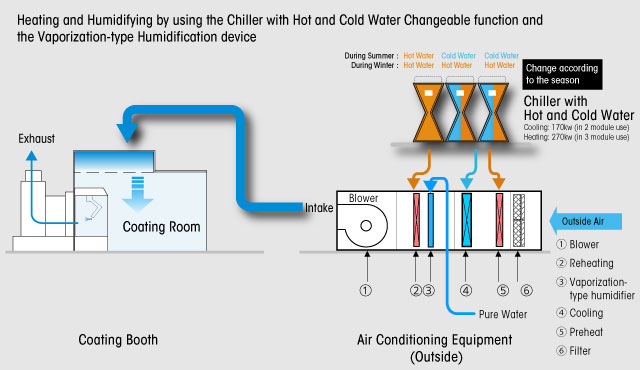

Takubo is pleased to introduce the Steam-less Air-Conditioning system having the module chiller unit with hot and cold water changeable function by high efficiency AC heat pump chiller and also vaporization-type humidifycation.

Advantages of the new AC system are as follows.

- Heat Pump Chiller used in this system is a high efficiency type of COP 5.5, which is more than two times of the old one 10 years ago, so the running cost is substantially reduced.

- CO2Reduction of Emissions

- Safe and Easy maintenace due to electricity use

The coating plant using this boiler-less AC system has got by 30% to 40% reduction of the AC energy running cost and CO2emissions.