Custom Jigs

Custom Jigs for SOFTBOY PRO

The purpose of the custom jig is not simply to rotate the work pieces. The jig must be optimized for the work piece to eliminate unnecessary movement by the robot and ensure high coating quality. It is also essential to achieve high quality and low cost in the design of the custom jig.

Custom jig examples

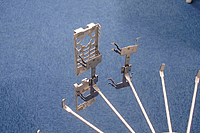

Example 2-stage work jig

The specification allows the top and bottom parts of folding handsets to be processed at the same time.

Example custom jig for magnesium mobile phone handsets

The specification raises up only the portion on which the work is mounted to accommodate a handling robot. Cleaning is efficient because coating material does not get onto the shaft.

Example mask jig

The specification allows coating of the outside only. The inside is covered so no coating material is applied.

Example special jig

The design of the custom jig is optimized to the specific work piece.